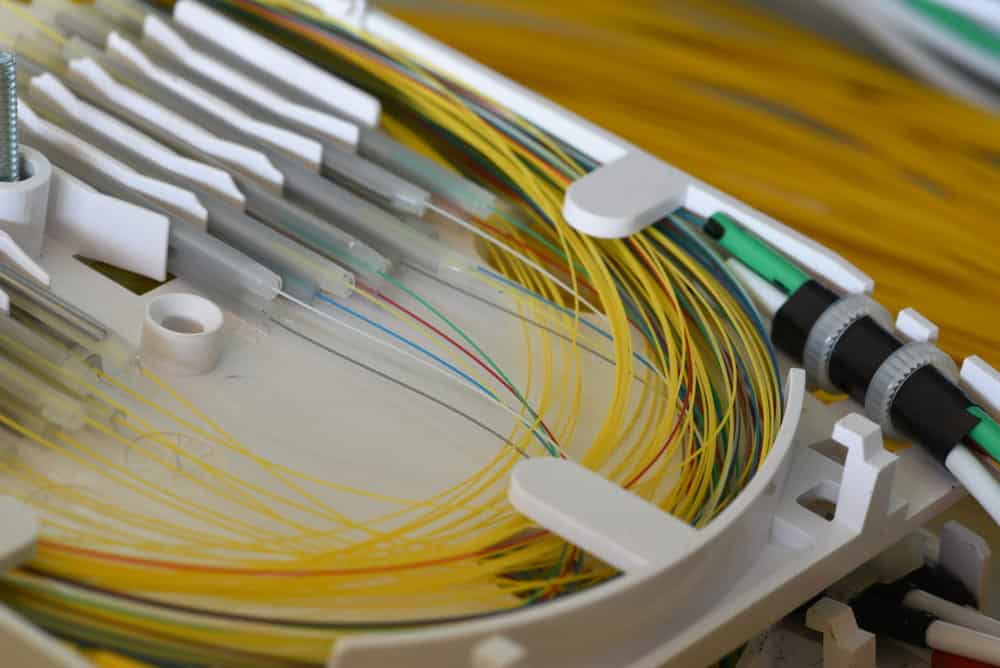

Fiber Optic Splicing

Fiber optic splicing is an effective yet constructive way as it connects two fiber optic cables. It can be the preferred option if the available fiber optic cable is not long enough for the necessary distance. Splicing is also considered as it repairs fiber optic cables when unexpectedly damaged.

It establishes a permanent connection between two fibers, such that their use is insubstantial to areas where cables are not likely to be obtainable for use in the future.

The most sought after used for splicing is concatenating (joining) cables in long outer plant cables where the continuance of the run requires more than one cable.

Splicing can be used to associate some contrasting types of cables, such as connecting 48 fiber cables to six 8-fiber cables from different placements. Splicing is usually used to terminate single-mode fibers by splicing pre-terminated pigtails on every fiber.

In addition, of course, splicing is used to recover the OSP. There are considerable instances where this may be necessary to add, repairing a damaged fiber cable, extending a fiber cable link, or introducing a new fiber tray or IANOS Module where the installation fibers need to be spliced to the pigtails within the tray.

As of today, fiber optic splicing is widely used in telecommunications, LAN (Local Area Network), and networking projects. Being a massive phenomenon, Splicing is most widely used in the field but is used in cable assembly plants as well.

Infield projects, splicing is a quicker and more effective process that is used to reconnect fiber optic cables where the buried cable is suddenly cut off. Typically, fiber optic splices can be seen in two ways: Fusing splices and Electronic splices.

Fusion Splicing

As it provides the lowest loss, an inexpensive reflectance and, the best as well as most steady joint, fusion splicing is mostly used. There are around two styles to access fusion splicing devices, either single fiber or a 12-fiber rope at a single time. Usually, all of the single-mode splices are fusion.

Moreover, a persuasive, uninterrupted, and non-reflective link between the fibers is established which allows very little loss of light transmission. The two stages of optical fiber fusion splicing that a fusion splicer regulates are:

- By aligning the two fibers based on their categories.

- By melting and combining the fibers by generating a minimal electrical arc.

Mechanical Splicing

Mechanical splices are calibration installation that connects two fibers ends together with an index glue between them. There is a variety of mechanical splices, such as V-shaped metal clamps or attenuated glass tubes.

Mechanical splice instruments are economical, but the splices themselves are more high-priced. Many mechanical splices are used for remodeling, but they can operate well with single-mode and multi-mode fiber, with practice-and with standard splices such as those used for fusion splicing.

This method is remarked for quick, temporary restoration and multimode fiber splicing. The fibers are scaled on the premises.

Mechanical splicing is used in cases if splices need to be produced very quickly and the costly melting splices are not usable. Much electronic fiber optic splice enables for both bonding and disconnection. In non-permanent cases, however, a mechanical splice may be used.

How Does It Work

The question is that which method is better? Well, it all depends on how precise you want the alignment to be, as better alignment usually results in a lower loss for which you have to pay more for that machine. Comparing or differentiating both of these methods depends on what industry you work in.

Mechanical splices work with single and multi-mode fiber while fusion splices work only with single-mode fiber.

Moreover, mechanical splicing produces more loss and more back reflection than fusion splicing because the fusion splicing points are almost seamless. However, comparing the methods of them might clear things up:

Fusion Splicing Method

The steps for the fusion splicing method are as follows:

- Strip the fiber by removing all of the protective coatings.

- Remove the jackets and tubes.

- Keep these cables clean.

- Then, you need to cleave the fiber.

- Make sure the cleave end face is perfectly flat.

- For a perfect splice make sure that the cleave end face is perpendicular to the axis.

- Next, fuse the fiber by carefully aligning and melting.

- Align the ends of the fiber carefully in the fiber optic splicer.

- Later, melt them to the two ends together.

- Now, use silicone gel or some heat shrinking tubes to protect this fiber.

- Using crimp protectors might also help to prevent any breakage.

Mechanical Splicing Method

The steps for the mechanical splicing method are as follows:

- Strip the fiber by removing all of the protective coatings.

- Remove the jackets and tubes.

- Keep these cables clean. The cleaning steps are the same as the fusion splicing method.

- Then, you need to cleave the fiber.

- Make sure the cleave end face is perfectly flat.

- For a perfect splice make sure that the cleave end face is perpendicular to the axis.

- It is essential to obtain the perfect cut on the fiber just like in the fusion splicing method.

- Now join the fiber, mechanically.

- Do not use a heat shrinking tube; join the two ends by using the index matching gel.

- As it can couple the light between the ends of the fiber, the mechanical splice’s apparatus handles it very neatly.

- To protect the fiber, do not place it in the splice closure first.

- Use the splice tray to place them and then use the closure.

- Keep in mind that there is no heat needed by the outside plant closures.

- To prevent any damage to the fiber by the moisture, carefully seal shrink tubing.

Both of these methods have their respective advantages and disadvantages. It all depends on the applications that tell us if we have to choose the fusion splice method or the mechanical splice method.

To ensure perfect fiber optic splicing, just follow the guidelines and make sure that all tools are clean and neat before undergoing any procedures.